If you’ve been looking at welding tables all over the place, your head is probably spinning trying to compare all of the options and make sense of them. I’ve talked to hundreds, if not thousands of customers over the years, and I feel bad for you! So I put together everything I could think of in an article called How to Choose a Welding Table: Materials, Types, Thicknesses, Ergonomics and More, and this Frequently Asked Questions list is basically my attempt at a supplement.

My hope is that between the two, you can’t possibly have any questions left about welding tables. If you want to buy one from us, fantastic! We’d love to get you one. But even if not, please review all of this info before making your decision because I want you to be armed with as much as I know about all these things. I may be the founder, but I’m actually in the rare position of not caring if you buy from us or not – as long as you get what you need!!!

Here’s a Table of Contents so you can TRY and jump to the right section, if that helps. Hopefully I’ve put it in a category that seems logical. Hit the little PLUS (+) on the right side of the question to reveal the answer.

Table of Contents

Buying and Choosing a Table

This is kind of a loaded question because there is no one-size-fits-all welding table. It’s going to depend on a lot of different factors, like what kind of budget you have, how much space you have, and how big the projects are that you want to tackle. But arguably, the size of the table is less important than the type of table. The most important thing about a welding table is how flat it is, followed by how usable is it.

In order to achieve flatness, you really need a three-dimensional table that has a rib infrastructure to support the surface. That way, no matter how much weight you put on it, it’s not going to sag underneath the weight.

Now, one of the other benefits of these types of 3D tables is that since they have side walls that are very perpendicular to the surface, you can actually bolt together multiple smaller tables in order to create one large surface. So this will actually allow you to initially invest in a smaller, higher-quality table and then later, if you find you need more surface area, you could buy an additional table and use them together.

In addition to bolting tables together, you can purchase table extensions that can be added temporarily or permanently, and you can even use things like Fab Squares to bolt to the side to temporarily support larger materials.

My general advice is to buy the largest table you can fit in your space if at all possible. If your space is limited (or your budget), it’s Ok – that’s what extensions and other bolt-ons are for. You can treat your table as modular and grow or shrink it as needed.

This question kind of assumes that there are so many different types of welding tables that one would be better for a hobbyist and a different one would be better for a professional. But in reality, the only real differentiator between a quality welding table for a beginner or for a professional has to do with the weight and construction of it.

Anyone engaged in welding needs a flat, stable surface, preferably with standard sized holes in it that can accommodate tooling for fixturing.

Now if you’re a beginner or a hobbyist, you would look for a table that is fairly lightweight and mobile because you probably don’t have a forklift sitting around and you need to be able to roll the table out of the way when it’s not in use.

- There are very cheap tables available on Amazon, at Harbor Freight, and Northern Tool. At a minimum start with one of those! It’s better than just throwing some legs on a piece of metal.

- But if you intend to actually weld for money, your table will be the most important tool you own. Treat it as such from an investment perspective. Oh, and your table will retain it’s value better than ANY other tool you own. It’s the one thing that won’t depreciate with use, because you won’t “wear out” a good table.

Conversely, if you’re a professional fabricator and you’re in a large shop, you probably have heavy lifting equipment like forklifts and you probably get engaged in larger projects where you’re going to need a big, strong, heavy table. Plus, you (HAVE A) commercial business that helps pay for the cost of an extraordinarily heavy and expensive table.

Not if you have room to accommodate it.

What tends to happen is that people buy a welding table and they get engaged in a project that might take a little bit to complete. If you have a small table, it’s fully occupied! And if you need to do some other quick little job, you don’t have any room to work. You either have to rush the original project, or you have to clear the table off and interrupt your work.

If you have a bigger table, you can handle small projects over on a corner of the table….

You’ll hear me say it over and over that I generally recommend you get the biggest table you can fit in your space. Because it seems like people ALWAYS find ways to use the bigger tables, and getting one too small will cost many times more in lost opportunity than just biting the bullet up front.

5/8” and 16mm tools are theoretically interchangeable. 16mm is technically 6.299, where 5/8” is .625. So the difference in diameter is only .049.

So if you see a tool labeled as 5/8”, it will definitely fit in any hole made for a 16mm tool. However, this is where things get tricky – there’s absolutely no industry standard for fabrication tables with 16mm holes! I wrote an article addressing this topic here.

This is such an individual preference issue, but there are still a few factors that may help make a determination.

Fixed vs Mobile

First, let’s address the issue of fixed vs mobile. This is mainly about the choice of casters or leveling feet on a table. With some manufacturers, there’s no caster option because the tables are so heavy (often 2,500-3,500 lbs) that it’s not practical to roll them. Plus they can’t get casters that will even handle the table plus additional weight. However, with fabricated tables like the sort Texas Metal Works builds, the tables are fairly heavy, but they can still accommodate casters and have thousands of pounds of capacity left.

Certain manufacturers who offer casters also offer an option that adds leveling feet as well. So you don’t have to choose between a fixed or rolling table. You can have one that will roll when you need it to, and then you just put the leveling feet down when it’s in the position you want and convert it into a fixed table.

Incidentally, two observations:

- Fixed tables almost always accommodate more weight because casters are generally the weakest link. For example, Texas Metal Works’ casters will hold about 1,200 lbs each, but the leveling feet are rated at 4,000 lbs each.

- Something like 90%+ of the tables we sell have casters. It’s what everyone wants, because mobility is a huge benefit. That’s why we have our casters made to our own specs, and offer the best in the industry.

Modular Tables

As far as modular tables are concerned, if we compare them to something like Texas Metal Works’ Mod Blox, they offer configuration to allow for open spaces where you need them and solid surfaces where you need them. This tends to work best for things like vehicle chassis, fences, railings, and other projects where you need a portion of the workpiece suspended but the rest open for access.

- Slotted top tables offer the ability to use clamps for holding workpieces directly on the table top.

- A solid top table makes it very difficult to hold parts firmly against the surface to keep the workpiece flat and prevent warping.

- Fabricators often tack things to solid surfaces and then later have to cut and grind them off.

- This results in a damaged surface over time that doesn’t lend well to precision work.

Slotted tables are very uncommon by themselves (here’s one), and it’s almost impossible to find tooling that’s interchangeable between manufacturers. I think it’s more of a way to lock customers into the purchase of proprietary tools… And I also think slotted tables are kind of the “poor manufacturer’s version”, because it’s easy to cut slots in a plate, but hard to cut a boatload of holes. Slots don’t even require accuracy!

Strong Hand does make some tables that kind of count as slotted, (like this one) in that they have individual plates that get bolted to a frame, and you can leave spaces. That raises a whole other set of issues, but let’s call those tables a hybrid because they also have holes for standard tooling.

A more standardized option would be to purchase a fabrication table with 16mm / 5/8” holes or their larger cousins, 28mm hole tables. Tooling for these is widely available and most should be interchangeable. You’ll find you have a much bigger selection of tools to choose from, and also lower pricing on a per-tool basis.

I don’t care what you buy, but you should have a VERY good reason for investing money in a slotted table. I would not recommend it.

When we talk about table top thickness, it’s important to differentiate between a 2D and 3D table top. If you’re simply taking a flat plate and welding some legs on it, a thicker top will result in more torsional rigidity, as well as resistance to deflection. However, if we’re talking about a modern 3D fixture table, these elements are already covered by the engineered design of the table with its supporting ribs and sidewalls.

A 3D table is about 30 times stronger than a 2D table, so then the real consideration with the surface plate thickness comes down to durability.

For the vast majority of users, even a 1/4” thick plate top, supported by dozens of ribs, is going to last a lifetime. If you’re planning on building bulldozers on the table, and will likely be dropping heavy components and abusing it like crazy, a thicker plate will provide more resistance to impacts and abuse.

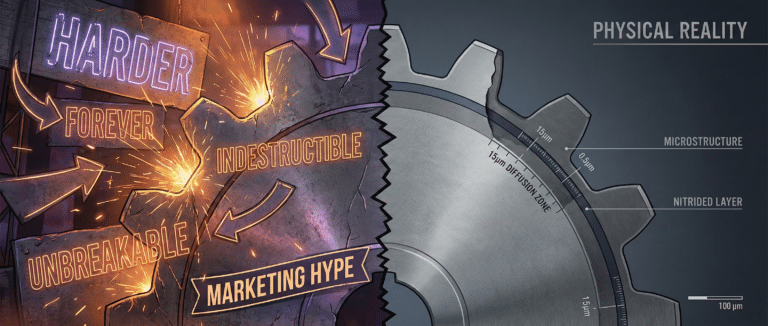

Although manufacturers like to make all sorts of marketing claims about how nitriding surfaces makes them “so much harder”, that is for the most part complete BS.

Yes! It does harden the surface layer of mild steel, but not meaningfully. For example, a 1/4” thick plate of A36 steel may have a Rockwell C hardness of 12 in its normal state. After nitriding, the surface may be in the 46-60HRC range depending on the quality of the treatment. BUT, that hardness only goes to a depth of… wait for it… LITERALLY – 0.0004–0.0012 in.! So imagine laying a super hard Kleenex on the surface of the table. Except that a Kleenex would be 10 times thicker!

So the bottom line is that nitriding only provides a thin crispy shell, like an M&M, which maybe prevents a little surface scratching but does absolutely nothing to protect from impacts.

Nitriding provides some surface corrosion resistance and some scratch resistance. However, the treatment is micro-porous and can crack. So even corrosion resistance is limited unless you add an oxide and a sealant. But you can’t do that on a welding surface! So nitriding will help the surface stain a bit slower, and maybe fingerprint less. But with any trapped moisture, it will damage quickly. It is NOT an anti-corrosion coating. Against corrosion alone, a freshly applied WD-40 film, especially the Specialist Corrosion Inhibitor, can outperform nitriding-only by a wide margin in salt-spray testing, often by an order of magnitude.

Bottom line: if you actively maintain it, WD-40 protection beats nitriding-only for corrosion resistance by a lot. Nitriding still helps with wear and stain resistance, but it is not a corrosion coating. So if it’s not good for corrosion, or for impact, what’s it good for?

You can purchase very cheap ($200-300) products on Amazon or at Harbor Freight that are marketed as fixture tables. For a hobbyist working on tiny, lightweight projects with no critical flatness requirements, they would work fine.

For a table with a demonstrably flat surface, fixture holes, and sturdy weight-bearing capacity, the price for a quality table is, very generally, around $1/sq inch of surface space. Premium tables made from thicker materials, fully machined, and with a surface treatment, may cost 2-3 times that.

In the US market, the two main DIY table kit providers are WeldProjects.com and WeldTables.com.

WeldProjects.com offers a much simpler assembly process with a self-fixturing design. The latter offers kits that are more difficult to assemble, but with proper assembly can still come out flat and strong.

Materials, Flatness, and Specs

First, we have an entire blog post here that deals with the topic of flatness.

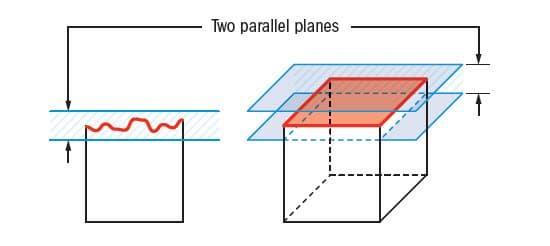

Having said that, there’s no single tolerance for flatness anywhere. Crazy, right?!? People love to throw around the term “aerospace” when they refer to things that are precise, but it’s not real. When scientists and engineers talk about flatness, they use the term Geometric Dimensioning and Tolerancing (GD&T). It means the highest point and the lowest point on the entire table surface must lie between two imaginary, perfectly parallel planes. So when we talk about welding table flatness, we basically mean what is the maximum deviation for any point of the surface relative to a flat plane running through the middle of it.

What’s acceptable is generally based on what has to be built on the table. For example, if you’re building fences, even 1/4” is just fine. Once you install the fence, no one will ever know. For a coffee table, 1/8” is great. Leveling feet are needed anyway because the ground isn’t flat. But for really important builds, you need a pretty flat surface because you can’t build anything flatter than the surface you’re building on.

High-end welding table manufacturers hold very tight tolerances on tables by starting with extremely heavy blocks and then machining every surface on giant milling machines. For example, Siegmund’s Spec guarantees no “dips” or “humps” greater than 0.0025″ within any given 1-foot section. Other manufacturers, like the highest-end table manufacturer Bluco, and even Texas Metal Works, do not provide a flatness guarantee for very practical reasons. A table can leave the factory with a perfect 0.004″ flatness, get strapped to a pallet, torqued by a forklift, and show up at your shop with 0.020″ of twist. Then it gets set on a concrete floor that isn’t level, and the spec is meaningless.

This is why properly leveling your table is so important.

Stop by your local hardware store and get you one of these:

- A new, high-quality carpenter’s level: A good 4-foot box-beam level often has a machined edge that is very straight.

- The factory edge of 3/4″ MDF: The factory-cut edge of a new sheet of MDF is typically extremely straight.

You also need a cheap set of feeler gauges from any auto parts store.

- Clean the Table: Wipe down the entire surface. Any spatter or debris will ruin the reading.

- Place the Straight Edge: Lay your straight edge (e.g., your level) on its edge diagonally from one corner to the other.

- Check for Light: Get low and shine (A) flashlight from the backside. This will instantly show you any gaps.

- Measure the Gaps: This is the key step.

- Slide the thinnest leaf of your feeler gauge (e.g., 0.002″) into the largest gap.

- If it slides in, try the next size up. Keep stacking leaves or using thicker ones until you find the one that just barely fits with slight friction.

- The thickness of that gauge is your deviation.

- Repeat in All Directions: You must check the table in a “star” pattern:

- Corner-to-corner (Diagonal 1)

- Corner-to-corner (Diagonal 2)

- Along the long edge (Edge 1)

- Along the long edge (Edge 2)

- Along the short edge (Edge 3)

- Along the short edge (Edge 4)

- Through the middle (both ways)

Result: This gives you a real number. You’ll be able to say, “My table has a 0.015-inch dip in the center.”

However, keep in mind that this is also dependent on the flatness of the actual straight edge you have! If you want to be as accurate as possible, perform the exact same measurements with both sides of the straight edge, add your measurements, and divide by 2 to get the average.

There is a difference between whether it might “work” in a pinch and whether you should do it at all. Technically, you can weld on just about anything. However, you risk lighting it on fire, or at the very least damaging it.

Generally, it would be a very, very bad idea to put a piece of metal on a wood surface and weld on it. That’s a recipe for starting a fire and would not be safe in any way. So NO, it won’t work as (A) welding table if we assume that one of the main functions of a welding table is to keep you safe.

If budget is a serious issue, you’re better off buying a super cheap welding surface from Amazon, Harbor Freight, or Northern Tool. Please do not weld on wood.

It depends on what you’re welding, and how abusive you intend to be.

We’ve built aluminum welding tables for people who needed a super lightweight, transportable surface. We build 304 stainless welding tables for people who are welding stainless or aluminum on the surface. And we use A572-50 steel for our production line of welding tables. One could argue that it’s overkill because it’s the hardest/strongest material being used in the industry. A36 is a fine material at a lower price point. Not as durable, but it’s steel.

We have an entire article that compares A36 to A572-50 in case you’re interested in the difference.

No, not really. At least not for the vast majority of people.

If we’re talking about 3D fabrication tables, with supporting ribs and sidewalls, the engineered block-style nature of the top already makes it about 30 times more rigid than even a 1” thick steel plate. So it’s not going to bend easily from what you’re doing on the top of it.

Additionally, it’s best practice not to even have the work material laying directly on the surface of the table. It’s best to use machined spacers to elevate the work above the table. It doesn’t affect flatness or accuracy, and it allows for downhill welds to not run into the table surface, and keeps the work exposed evenly to air so it can cool evenly and not act like it has a giant heat sink on one side and air on the other.

Having said that, if we’re talking about heavy industry manufacturing where you’re welding 2”+ thick plate all day long every day, you’re going to be using some of the biggest, heaviest tables made by companies like Bluco or Siegmund. In that case, you’d also have the heavy lifting equipment to deal with those big boy tables as well.

In Europe and the rest of the world that adopts the metric system, tables have 16mm holes spaced on 50mm centers. In the US and countries that work off the Imperial system, we build tables with the same sized holes on 2” centers. Technically, 2” = 50.8mm.

And No, it doesn’t matter.

The spacing of the holes means nothing at all. The main reason they are roughly spaced this far apart is to ensure that when you need to mount a tool to the table, you can basically reach every square inch of it. The same tools will fit in tables with spacing of 50mm or 2”, because the holes are identical.

Grounding, Electricity, and Safety

When you’re welding in general, and using any table, it’s safe and routine practice to clamp your ground to the table and place your work material on the table. It’ll allow the current to pass through, and almost every welder does this every day.

I’m also making the huge assumption that your clamping spot and material on the table are clean and don’t have dirt, paint, or other things on them. Rust, mill scale, paint, oil, or slotted/sectional tables with poor bonds add resistance.

Having said that, when you clamp to any piece of metal that’s in contact with the one you’re welding, instead of directly clamping, there’s going to be some energy loss. With a clean table and good contact, we’re talking about like 1%. But if you are clamped very far away, to a dirty table, you might see a 5-10% voltage drop. If you’re using MIG, you might not notice. But with a certain process on certain materials, like TIG on thin aluminum, you might see erratic arc starts, arc wander, or poor cleaning action.

One way to get around this issue (but only for steel) is to replace the clamp on your welder with a magnetic ground clamp. I’m a big fan of the Magswitch 300 Amp Magnetic Welding Ground. I leave it attached to my welding table, but IF I want to move it to my workpiece, it’s super easy and you don’t have to worry about being able to literally clamp since it’s just a magnet.

As long as the power strip is electrically insulated, it’s no problem. Make sure your power strip is a high-quality, UL-listed unit and that there aren’t any exposed wires or anything.

If you want to be extra careful, you can attach a piece of non-conducting material like wood or HDPE to a spot where there will not be any heat, and then screw the power strip onto it. You must make sure that you are using two sets of connectors – screws or bolts from the HDPE to the table, and different ones to the power strip so there is no continuous connection.

A bigger concern is probably that welders are often using grinders near their tables, and spewing metal dust directly into electrical outlets is a very, very bad idea. So keep those things far apart.

The MIG welder, fine. The gas bottle, ABSOLUTELY NO WAY!!!

You want some distance between your welding and a gas bottle. If you were to accidentally arc to the weld bottle, it could weaken and rupture the tank, leading to a catastrophic – potentially deadly – situation. Plus, any tank that has had an arc strike can no longer be filled. It’s hundreds of dollars down the drain.

Workholding and Accessories

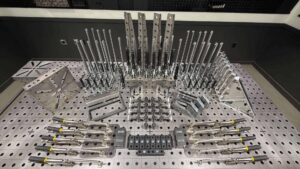

Texas Metal Works has a hand-picked kit of accessories for beginners that contains the most basic and useful tools for general-purpose fixturing.

The product listing page has a long description of each tool and WHY it might be useful. I’d love to answer it here, but it’s a LOT of info, so best to look through that page.

Both can be useful, but T-slots don’t have many vendors or accessories available. The 16mm holes are industry standard, so those will offer an infinitely larger pool of tooling to use with your table. And there are threaded hole adapters that will allow you to convert a standard hole to a threaded hole.

Once you’ve inserted the threaded hole adapter, it can be very useful to bolt projects directly to the table, and doing so will hold them far tighter than any clamp ever could.

So I would almost never recommend tapping holes on the surface of the table because then you definitely can’t use a standard tool in that location. Plus, eventually the threads will be damaged. So better off to just use a cheap, mobile adapter.

Rule #1: Apply anti-spatter spray liberally.

At Texas Metal Works, we buy Weld-Kleen anti-spatter by the 5-gallon containers and we use it all day, every day.

Before you work on a project, clean your table surface (you should be in that habit anyway) and then spray anywhere you might be welding near. You can actually spray down your whole table with it because it includes rust-retardant ingredients. So it will protect from BBs sticking to your table as well as help keep it from rusting.

Bonus tip!!! You can actually spray the anti-spatter directly on the parts you’re welding! Then make your welds right through it. It will also keep the BBs from sticking to your work where you’re welding!

Generally speaking, any sort of angle tool purchased commercially should be pretty accurate. The difference between one marketed as “precision” may be literally the word. But it might be a fraction of a degree more accurate.

Typically, the difference between a fabrication square and a normal one is that it will include some extra flanges or holes for clamping or bolting material to. That certainly makes your life way simpler.

Table Movement, Rails, and Shop Layout

It’s not hard. Just takes patience. Generally speaking, start with just a single table.

- Run the leveling feet out about halfway, and then get that table leveled up in its final resting spot.

- Bring the next table over and set it in place beside the first table, and place a straightedge spanning across the two.

- I recommend clamping (IT) to one of the two (generally the one that is higher at the moment).

- Begin adjusting the leveling feet on the newly adjacent table until the straight edge demonstrates that they are on the exact same plane.

- With precision tables, you can also run your finger across the joint and it should be obvious the tables are level.

Some vendors do indeed offer rail systems. Strong Hand Tools, Siegmund, and Bluco all have floor mount systems. However, they are extremely expensive.

They have floor-mounted, machined rails that can either be surface mounted (creates a tripping hazard), or recessed (requires concrete work). Then you order special legs for the table tops which are designed to roll along the rails and be pinned in place.

If you don’t absolutely need a rail system, there are far simpler and less expensive ways to accomplish this. For example Texas Metal Works offers all of the fabrication tables with casters, leveling feet, or both. If you opt for both, you can roll tables into position, and then use the leveling feet to level them up when you have them where you want them. Just takes a few minutes, and you don’t need to tear up the concrete in your facility and spent tens or hundreds of thousands of dollars on special rails and legs.

You can simply bolt a steel plate to the floor, place the table on top, and tack weld the leveling foot to the plate. You’ll still be able to turn the leveling adjustment!

You can certainly do that, but it’s simpler to just use leveling feet on the table legs and tack them to the plate on the ground.

If you use two plates, you’ll still have to tack the feet to the top plate so the table doesn’t shift off. There is really no need to do that since the leveling feet can still adjust height when welded to the plate.

Maintenance and Longevity

The Texas Metal Works’ blog has an article specifically addressing long-term care of any steel table.

#tldr version:

- If the table has rust that needs to be cleaned, a cheap burnishing tool works great.

- WD-40 periodically sprayed on the surface will completely prevent rust.

- OSPHO treatment on the surface will protect for up to a year.

- Weld-Kleen 350 prevents spatter from sticking and has a rust preventative agent.

We’ve tried ALL of them, and we use Weld-Kleen 350. You can buy it by the 5-gallon container, and it has a rust inhibitor in it as well. So while it’s preventing spatter, it also protects against rust.

If you have a Porta Power hydraulic spreader–puller, you may be able to attach some chains in various positions on the table and either push or pull the bow or twist out of it. The challenge is that it’s going to spring back as soon as you let off the pressure, so when you get it in position you might need to take some support material like steel tubing and weld it to the table before removing the tension.

The other option is to NOT try to fix the warp but instead work around it. This is what I would actually recommend, because you could damage or weaken the table further by trying to force it back.

So instead, get some thin shim material and build it up by welding it to the surface strategically to create an artificial surface that is indeed flat. So let’s say that the table had warped to a point where the middle is depressed by 1/8”. Lay a long straight edge across the high points and then shim up the low points progressively every 6 inches or so to build them up. As long as you can lay your material across the elevated points, you’ve got no problem! You’re just creating an elevated surface!

You could also do this by simply welding on the surface and building up material. Then once it’s elevated, gently use a flap disc to bring it down until you’ve established a flat plane.

If your nitrided top is starting to look scratched and worn, that’s normal. When nitriding, only the top .0002” or so is even affected. And something as simple as laying a wet towel can damage the surface. Generally speaking, you can just completely ignore it.

If your nitrided surface has pits and other physical issues, you can selectively use a flap disc to remove protrusions, and you can weld in filler material to plug gouges and then use your flap disc or a sanding block to flatten them back to surface level. If you had a big enough milling machine, or even a surface grinder, you could absolutely just shave a little off the whole thing without any ramifications.

No matter what you choose, just follow our simple tips for protecting the surface from rust and it’ll still last forever.

Shipping, Assembly, and Vendors

3D Fab tables can be quite heavy, and depending on the size and type, it’s very possible liftgates can’t handle them.

To start with, liftgates generally can’t handle anything larger than 4’x8’. And some can’t even handle those dimensions. They are simply too large to roll out and clear the truck with a pallet jack.

Some tables, such as those advertised as super heavy-duty with very thick walls, can weigh 2,000 – 3,000 pounds even in smaller sizes. Those are going to be right out because you can’t count on a truck having a liftgate that can handle more than 1,500-2,000 lbs.

Tables like the ones we build at Texas Metal Works can get liftgate services up to our 40×80 units for sure, with no weight problems.

If you’re trying to get a bigger, or heavier, table than a liftgate can handle, and you don’t have a forklift, we’ve seen people do a number of things:

- Use a farm machine like a tractor with forks to unload.

- Have the table shipped to their work location or a friend’s location with a forklift, then take a trailer with a roll-off liftgate over there to bring the table back to your location where you can roll it off (if you got a unit with casters), or potentially hoist it off if you have something like a small bridge crane.

- Have the vendor (TO) ask the LTL carrier to hold the shipment at the nearest terminal and drive over to the terminal with a trailer to pick it up.

This is going to vary wildly by manufacturer. If you’re talking about a DIY Weld Table kit, WeldTables.com quotes 4-6 weeks. WeldProjects.com and Texas Metal Works quote 2-3 weeks.

Both manufacturers offer designs that have tabs and slots to make assembly easier with parts generally snapping together. Only WeldProjects and Texas Metal Works have self-fixturing components to allow the kits to be assembled with bolts and capture nuts. Here’s a video demonstrating assembly:

Some do, some do not. It’s not about which ones can build a flat surface; it’s more complicated than that.

For example Bluco, probably the highest-end table maker on the planet, gives no flatness guarantee – though they are probably the flattest you can get. That’s because a table could leave their facility perfectly flat, but after being strapped to a pallet, forklifted around, and placed on an uneven floor, it might not measure as flat any more.

However, if you mount any professionally manufactured table to the floor and use the leveling feet provided, you should be able to get the table exceptionally flat.

Siegmund and StrongHand both offer roughly the same guarantee, which amounts to basically no “dips” or “humps” greater than 0.0025″ within any given 1-foot section.

Got More Questions?

If I didn’t get your question, or even if I did but you have follow on questions or need more clarification, feel free to contact us and one of our team members will help with whatever you need.

If you really want to talk to me, you can tell any member of the team that you’d like to get my advice. Just let them know you’re NOT trying to sell me something. Because they try not to let telemarketers waste my time. 🙂