Texas Metal Works Product Reviews

We are SOOOO appreciative when our customers leave a product review. It’s a nice way to let our team know we did a good job, and it’s also a great way for prospective clients to get a feel for how those who went before them feel about their purchases. A huge thanks to everyone that takes the time to let us know how we did!

| 5 star | 91% | |

| 4 star | 7% | |

| 3 star | 2% | |

| 2 star | 0% | |

| 1 star | 0% |

I ordered the 50×100 table and received it in great condition. The table is solid and extremely flat. I have been using it for about 4 weeks and it has changed how accurate I can be and is much more efficient than welding on a sheet table. I also ordered fixtures tools and am loving the quality of those as well. I have left reviews on Google and Facebook and will be Happy to suggest Texas Metal Works to anyone who needs a high quality fixture table and is also on a budget.

The production set up that I was able to do with this table saved me hours of work. It keeps things precise, the attachments fit perfectly, and I couldn’t be happier with my purchase.

I am an art welder and not a professional fabricator so even though I have 10 years of experience welding, I have never had any classes and am strictly a novice or amateur. Nevertheless, I found putting the table together by following the video went exactly as planned without any issues whatsoever. It truly was just as easy and methodical as the video implies. The driver rolled the pallet up into my garage without even asking him to do so with the liftgate service. I realize this depends entirely on the driver and their disposition, but it was very helpful. I love the table and it went together easily. All of my experience with the company was very very positive Including a conversation with John, which helped me figure out which option would be best for me. I would highly recommend Texas metalwork to anyone looking to purchase a table.

Our team is extremely happy with the purchase of this table and all the accessories.

The workmanship, pricing, delivery, etc. is on point and we have zero complaints!

Additionally, having this new table has inspired everyone to now go thru a full overhaul of our fabrication area.

Serious table for serious work

Texas Metal Works tables are not cheap; they are actually quite expensive (compared to box store offerings). That being said, these tables are a great value. Serious tables for those who want to do real quality, serious work. TMW tables are on a completely different level of quality and craftsmanship than the crappy offerings from Northern Tool or Harbor Freight. I am a hack fabricator / welder, but my skill level increased five-fold with this table. The tables were designed by folks who know what the fitter/welder needs to make quality welds: A heavy work platform with no give that is flatter than flat, built for use with a system of stops and clamps that keeps the work in place at the proper angle and position while you weld.

When I bought this table and all the stops and clamps and extensions, I thought that I was spending too much. Splurging. As soon as the table arrived and was outfitted in place, the splurging feeling changed into an investing feeling. A very satisfied feeling. I had invested in a high quality tool ( like buying a good Wilton Machinists vise or a Quincy Air Compressor) that becomes an heirloom. Your son or daughter will also value this table one day if that is their direction. By the way, you really need to get a good array of the stops, clamps, extensions to really unleash the power of these tables. Also, all of the advice provided by the Pozadzides is quite sound and valuable; get the pallet fork extensions for unloading (if you live on a farm), the WD-40 by the gallon for protecting the table, and the magnet handles for lifting and handling the table covers. The table was well packed and delivered, with no surprises thanks to the pallet fork extensions.

Do yourself a favor and invest in a quality fabricating and welding table. Texas Metal Works is it. HIGHLY RECOMMENDED. The only downside is that you can’t use “crummy equipment” anymore as an excuse for bad welds once you have one!

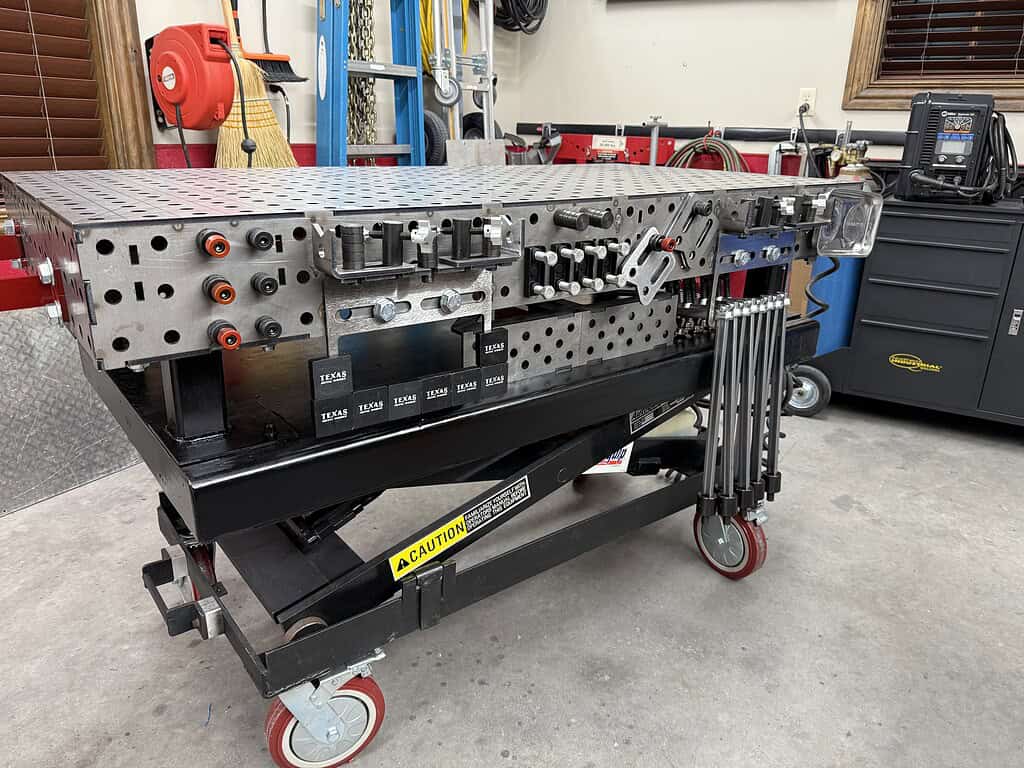

Excellent table. Very well built. I mounted it to a hydraulic table and it worked out perfectly.

Arrived very well packaged & quick to set up. Quality of the table is great.

great customer service, table arrived well packaged and exactly as ordered.

Was contacted before delivery to ensure we were prepared and that everything would go smoothly, letting me know what to expect and how to handle the table.