Description

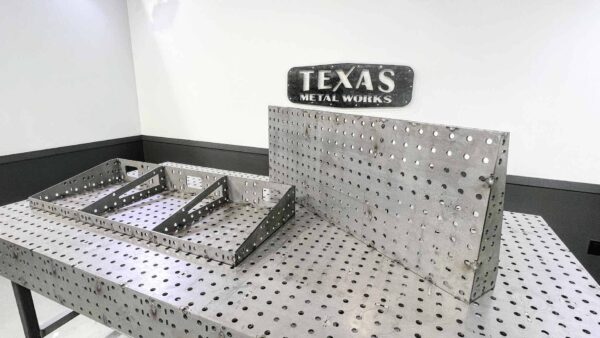

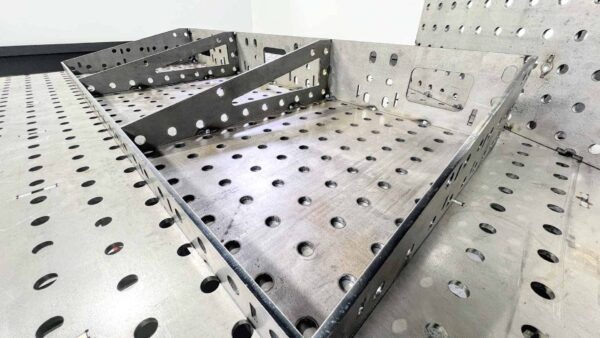

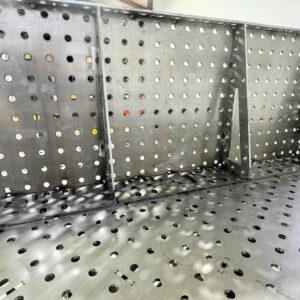

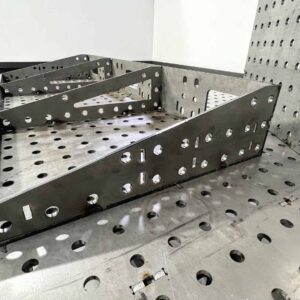

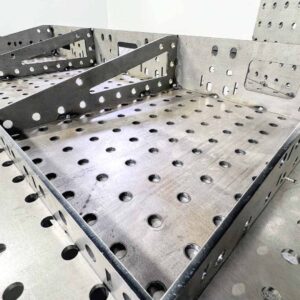

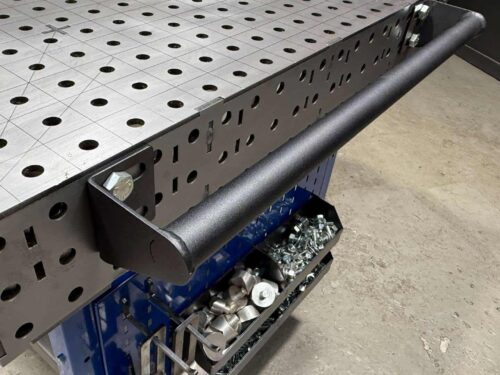

Our welding table extensions can be used for a wide variety of purposes, not the least of which is to extend the length of our welding tables. By bolting these extensions to the sides of a table the length or width can be increased by 20″ (single) or 40″ (pair).

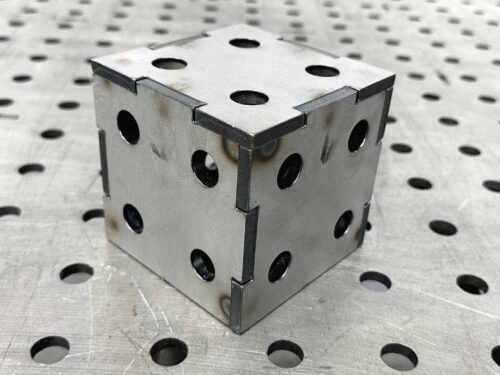

The extensions can also be used as full-length (or width) 90-degree squares for fabricating things that require precision angles. When used in combination with our Fab Squares it’s possible, for example, to perfectly fixture all of the legs for a table at perfect dual 90-degree angles.

Available Extension Sizes

The Welding Table Extensions come in five widths and two different depths:

- 20″ x 10″ (Gen 1 or Gen 2)

- 30″ x 10″ (Gen 1 or Gen 2) or our deeper 30″ x 20″

- 40″ x 10″ (Gen 1 or Gen 2) or our deeper 40″ x 20″

- 50″ x 10″ (Gen 1 or Gen 2) or our deeper 50″ x 20″

- 60″ x 10″ (Gen 1)

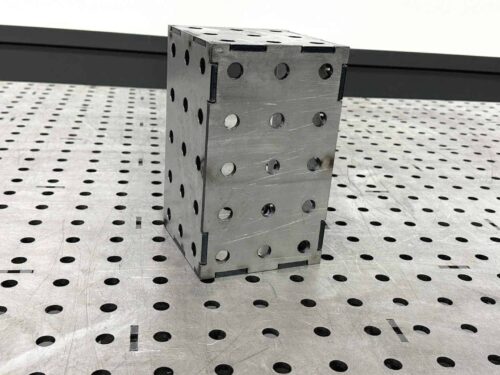

Double up and expand your table by 20″ or 40″. These add-on extensions transform provide flexibility to accommodate larger projects. Also, don’t forget our extensions can also mount topside to create height for fixturing.

Also, keep in mind the smaller sizes are often purchased exclusively to use as large squares on the surface since they don’t cost much more than a couple of 6″ wide squares, but can be deployed more quickly and ensure evenness along a line of fixturing!

One last thing to keep in mind. Even if you have a big table, you can use the smaller extensions, like the 20″ units, to only extend the table in certain spots to accommodate extra-wide fixturing. Then, when you aren’t using them to extend the table, use them on top as big squares!

Eric S. (verified owner) –

David W. Hill (verified owner) –

Love these! Glad I got with my order as they have already been needed and used on my first build with your table. Love the fact that I can have on side to widen table or move the to end to lengthen table. I love the flexibility of how many ways they can be used, on the sides, ends or on top if I need a wall. Glad I have them!!!

Only suggestion for these is if you could incorporate the grid pattern you have etched on the table top to continue onto these. Would think not too difficult for programming into CAD when cutting out as you have everything else matching up so well when you are cutting out. But then again I am not a programmer, just a suggestion for future tables and as you grow your company 🙂

There is no review on the leveling feet I never really got.

I sent an email to John on 6/26/24 following up on the box of what should have been my missing 8″ T-clamps and missing leveling feet. I was sent the 300mm T-clamps and leveling feet screws. I received the box broken up and only 3 of the leveling feet were in there, not 6 that my table requires. Again, I never heard back from anyone at Texas metals after sending John this last email.

I am sending you this review as I want to see your company grow and continue. If I can help you get over your growing design pains, it ultimately helps me. I think you have a great welding table design and products to go with it. Your products are helping me give my customers a better quality product where we all win. At the same time, for $9000 I paid, I don’t think I should have to be spending the hours I will need to to correct simple design flaws that QC should have caught. Thank you, David Hill

Daniel B. (verified owner) –

Truly needed when a logger job comes in. I’ve found that these make very effective extensions without too much hassle mounting then in place. They can even be used on the top of the table is you need multiple fixture points.