First, we have an entire blog post here that deals with the topic of flatness.

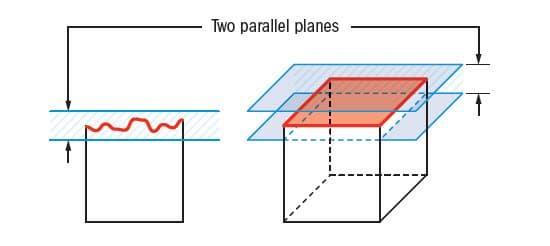

Having said that, there’s no single tolerance for flatness anywhere. Crazy, right?!? People love to throw around the term “aerospace” when they refer to things that are precise, but it’s not real. When scientists and engineers talk about flatness, they use the term Geometric Dimensioning and Tolerancing (GD&T). It means the highest point and the lowest point on the entire table surface must lie between two imaginary, perfectly parallel planes. So when we talk about welding table flatness, we basically mean what is the maximum deviation for any point of the surface relative to a flat plane running through the middle of it.

What’s acceptable is generally based on what has to be built on the table. For example, if you’re building fences, even 1/4” is just fine. Once you install the fence, no one will ever know. For a coffee table, 1/8” is great. Leveling feet are needed anyway because the ground isn’t flat. But for really important builds, you need a pretty flat surface because you can’t build anything flatter than the surface you’re building on.

High-end welding table manufacturers hold very tight tolerances on tables by starting with extremely heavy blocks and then machining every surface on giant milling machines. For example, Siegmund’s Spec guarantees no “dips” or “humps” greater than 0.0025″ within any given 1-foot section. Other manufacturers, like the highest-end table manufacturer Bluco, and even Texas Metal Works, do not provide a flatness guarantee for very practical reasons. A table can leave the factory with a perfect 0.004″ flatness, get strapped to a pallet, torqued by a forklift, and show up at your shop with 0.020″ of twist. Then it gets set on a concrete floor that isn’t level, and the spec is meaningless.

This is why properly leveling your table is so important.