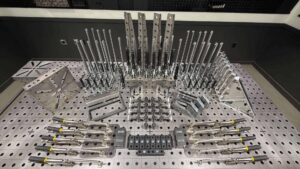

- Slotted top tables offer the ability to use clamps for holding workpieces directly on the table top.

- A solid top table makes it very difficult to hold parts firmly against the surface to keep the workpiece flat and prevent warping.

- Fabricators often tack things to solid surfaces and then later have to cut and grind them off.

- This results in a damaged surface over time that doesn’t lend well to precision work.

Slotted tables are very uncommon by themselves (here’s one), and it’s almost impossible to find tooling that’s interchangeable between manufacturers. I think it’s more of a way to lock customers into the purchase of proprietary tools… And I also think slotted tables are kind of the “poor manufacturer’s version”, because it’s easy to cut slots in a plate, but hard to cut a boatload of holes. Slots don’t even require accuracy!

Strong Hand does make some tables that kind of count as slotted, (like this one) in that they have individual plates that get bolted to a frame, and you can leave spaces. That raises a whole other set of issues, but let’s call those tables a hybrid because they also have holes for standard tooling.

A more standardized option would be to purchase a fabrication table with 16mm / 5/8” holes or their larger cousins, 28mm hole tables. Tooling for these is widely available and most should be interchangeable. You’ll find you have a much bigger selection of tools to choose from, and also lower pricing on a per-tool basis.

I don’t care what you buy, but you should have a VERY good reason for investing money in a slotted table. I would not recommend it.