Welding Table Overview Video

Welding Table Description

Texas Metal Works offers fully fabricated tables shipped FREE – saving you time, hassle, and money! If you need a 5′ x 10′ welding table / fabrication surface, our 60″ x 120″ welding table is one of the biggest in the industry, and the largest table in our lineup. When it comes to having plenty of room for multiple stations, or just accommodating very large products, it can’t be beat.

The surface is a true 60″ wide and 120″ long, and the 8″ sidewalls allow for additional fixturing outside of the table dimensions. For even MORE room, you can always add one or more of our welding table extensions. That makes it possible to increase the work surface to an astonishing 70″ x 140″!

Table Top Features

- A full 60-inch wide x 120-inch long work surface with 8-inch side walls.

- Available in 1/4″, 3/8″ and 1/2″ (A572-50) thickness table tops with 1/4″ sidewalls and rib structure.

- Standard 38″ surface height (Check out Custom Height – Cut To Order).

- Accommodates 5-foot x 10-foot materials with plenty of room to spare!

- Over 2,500 precision CNC cut holes (5/8″ / 16mm).

- Accommodates Stronghand and similar tooling.

- Professionally assembled and guaranteed forever!

Table Base Features

- 2″ x 11 gauge heavy tubular steel legs with 2″ x 16 gauge tubular steel cross bracing.

- Optional Casters: 8″ swivel and fixed casters with Total Lock Brakes rated over 1,200 pounds per wheel. Non-marking polyurethane wheels with iron hubs.

- Optional Leveling Feet: Glass-fibre reinforced tube ends and self-leveling swivel stud feet.

- Weighs approximately 1,400 lbs. with legs and casters.

Table Customizations

- Check out our line of BASE SHELVES, DRAWERS, EXTENSIONS, and REMOVEABLE COVERS.

- For fixturing and productivity, check out our: RISER BLOCKS, FAB SQUARES, and SUPER SLOT ACCESSORIES.

- Need a splash of color and some anti-rust protection, check out POWDER OPTIONS

- Need a custom height table (standard top is 38″)? Check out Custom Height (Cut To Order)

Customizations

- Check out our line of BASE SHELVES, DRAWERS, EXTENSIONS, and REMOVEABLE COVERS.

- For fixturing and productivity, check out our: RISER BLOCKS, FAB SQUARES, and SUPER SLOT ACCESSORIES.

- Need a splash of color and some anti-rust protection, check out POWDER OPTIONS

- Need a custom height table (standard top is 38″)? Check out Custom Height (Cut To Order)

Welding Table Components

Complete tables are built from dozens of laser cut parts, which is just one key component to the overall accuracy of the finished product. Sure, our CNC machines can maintain accuracy to within .002″, but let’s face it – a stack of parts isn’t going to perfectly fabricate itself!

Welding Table Construction

Read our full article: How We Build Super Flat Welding Tables

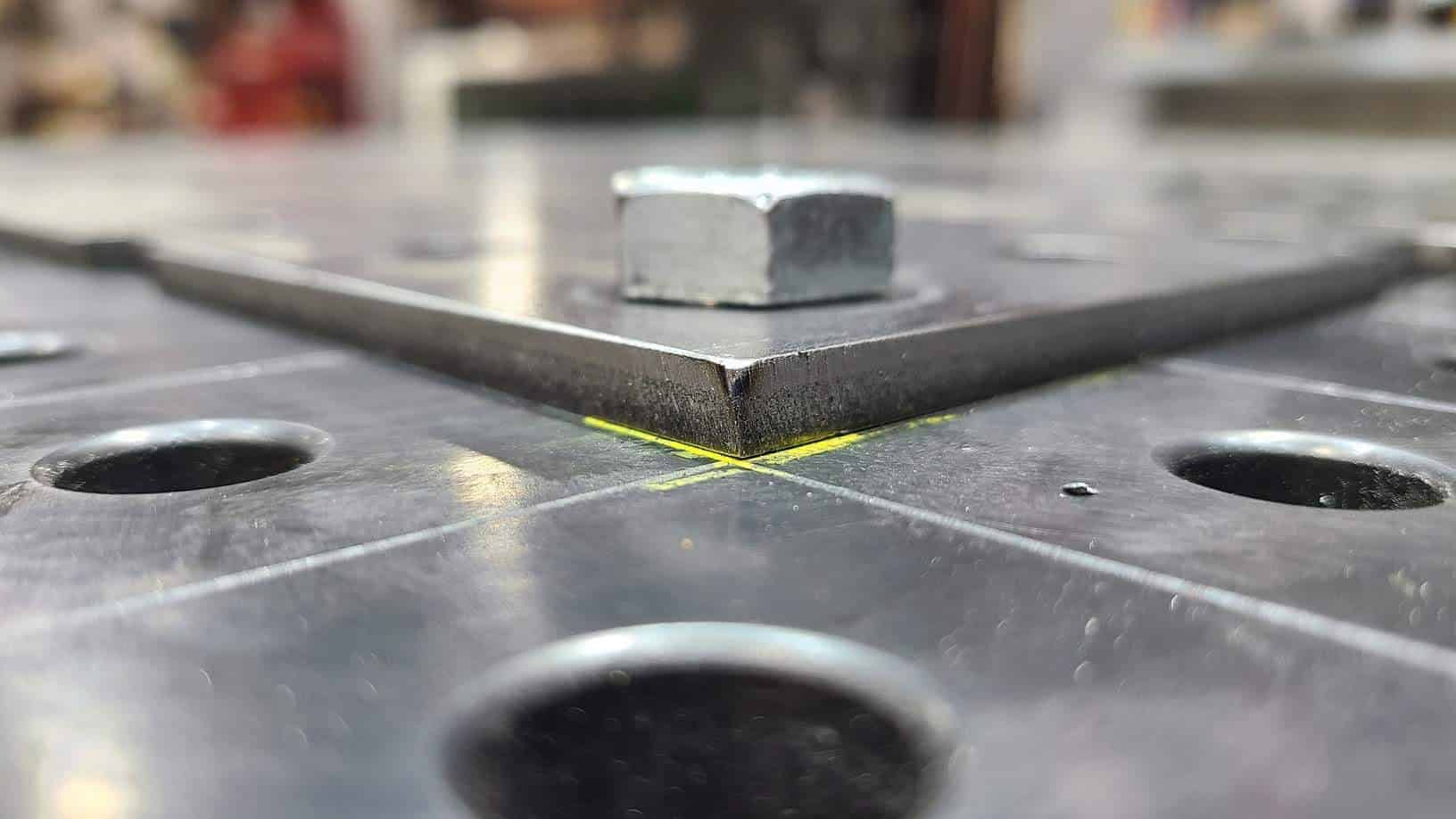

The strength of a Texas Metal Works weld table comes from the interlocking series of ribs supporting the surface. These precision cut ribs lock together and also interlock with the table surface.

As you might guess, fabricating a huge table with precision requires extraordinary effort and a lot of practice. But we also augment our fabricator’s experience with the best tools available. In addition to using 142 bolts, 132 feet of threaded rod, 63 fixturing plates and making hundreds welds – we also fabricate all of our table on a heavy duty milled reference surface!

You can read a complete discussion of our welding table build process here, but the short version is that we start out by securely bolting every table top directly to a precision milled surface.

Only after securing the top to a reference surface do we add the ribs and sidewalls and secure them by bolting everything firmly in place before locking it in with hundreds of weld points.

At the end of the day, we’re not happy until we can lay a level across the surface and visually verify that there is almost no (or none whatsoever) daylight peeking through.

Related Information

- How to Keep Welding Tables from Rusting.

- Accessories that work well with our welding tables.

- Understanding welding table flatness.

Notes on Shipping

As you can imagine, these massive tables can be a little challenging to ship and receive. When we ship any of our tables the carriers require us to put them on a pallet. But normal pallets won’t work, so we manufacture custom pallets specifically for shipping these bad boys.

Each table is bolted directly to a custom pallet with heavy-duty hex head screws to ensure it stays put during transport. If you choose the option with casters or purchase accessories, they’ll be placed in a box and safely strapped to the pallet.

Blue heat shrink wrap is used to protect the tabletop against dust and water. It also serves as the perfect visual indicator of topside damage resulting from delivery. We encourage customers to fully inspect their tables upon delivery and before signing the trucking company’s Bill of Laden.

Pallets are loaded onto a truck at our dock via forklift, and we use long fork extensions to put them in the truck. Shipping companies only carry a small pallet jack on the truck, and those jacks can reposition many of our tables up to our 40×80 size. Larger tables can’t easily be moved via pallet jack. So on the receiving end, it’s going to require a similar setup for unloading purposes. Please note: If you don’t have a forklift, you’ll need to purchase optional Liftgate Services.

At a bare minimum, you’ll need 48″ forks to lift the table out of the truck. For our 40×80 or larger tables, we recommend 72″ or 84″ fork extensions. Amazon sells a bunch of extensions in case you need them. We’ve used these 72″ fork extensions to get the job done, and these 84″ fork extensions work even better. When buying forklift extensions pay particular attention to the width of your forks to make sure you get the right size!

If you can get heavier-duty fork extensions we HIGHLY recommend it! Especially if you order your table along with several accessories that will ship on top. The tables plus accessories can often exceed 1,000 pounds, and the light-duty extensions may flex or bend. Please contact us if you have any concerns about receiving, or if we need to make special plans to get things delivered safely!

Lift Gate Not Available

A forklift and/or dock is required for delivery. Most liftgates can handle freight that is equal to or less than 96 inches wide, and 48 inches deep. The weight limit on a standard liftgate is 2500 lbs. Sadly, this table cannot be safely lowered to the ground via liftgate. That said, customers without a forklift or dock will need to identify an alternative means of delivery.

Many of our customers rent a 6×12 Utility Trailer with Ramp from UHaul and transport it to their home/business. Typically, customers will arrange to pick up at the local LTL terminal or ship to neighborhood suppliers (like gas companies). Once there, the supplier can use their forklift to unload the table and the customer can quickly install casters and transfer the table to a utility trailer with a ramp. Upon arrival, the table can safely be rolled off the trailer’s ramp and into their facility!