If you pick up one of our exceptional welding tables you may be wondering what to do with all of those fixturing holes! Well, this article will outline some of our favorite options.

Clamping

The holes on all of our tables are cut to accommodate “standard” tooling that is labeled as either 5/8″ or 16mm. So you can add basically any of Strong Hands Tools InsertaClamps. We highly recommend the 6 1/2″ InsertaClamp as pictured here. One of the best things about these clamps is that they can reach all the way down to the surface of the table to hold very thin materials.

We also like the ratchet handle InsertaClamps for their fast action locking and releasing. But the one drawback is that they can only clamp material that is at least about 1″ tall.

Another tool that can be quite useful is a BuildPro Stop. These can be inserted so you can push material up against them to hold in place.

You can also get stops that are capable of pushing back!

Fixturing

Now that we’ve covered actually securing material to the table, it’s also important to be able to hold thing exactly where they need to be! That’s where fixtured can come in really useful.

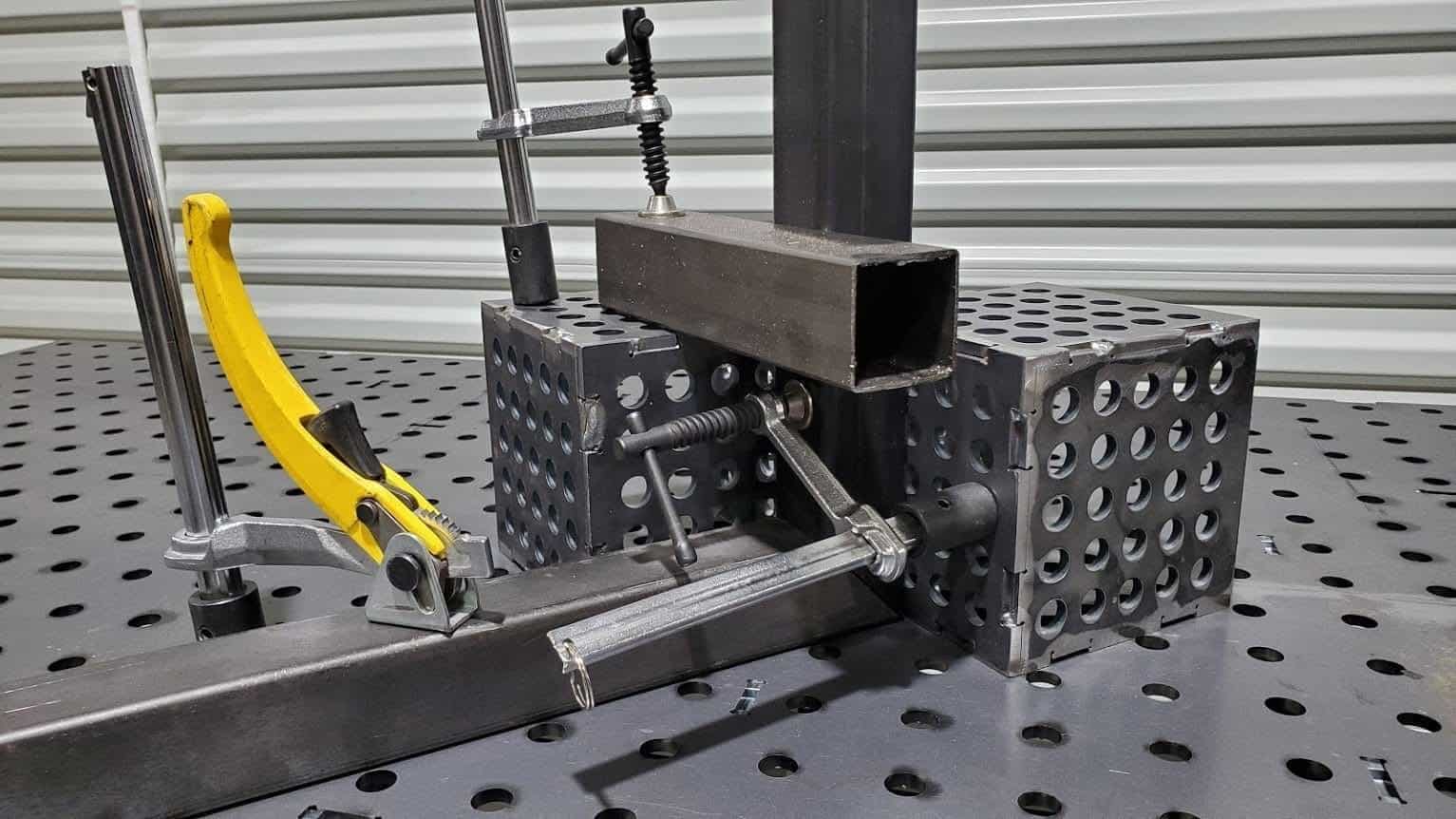

One of the most important things you can do is hold material at a true 90 degree angle. And we offer a number of Weld Angles that bolt or clamp directly to the surface of our weld tables. These angles allow material to be clamped and held securely while you weld.

Riser blocks can also be useful for fixturing at 90 degree angles, either with C-clamps, or with InsertaClamps.

And since they offer a flat surface they are also useful for clamping down on taller items that a clamp alone simply can’t reach.

If you have other specific fixturing needs and can’t find a standard tool to take care of them, just let us know and we can always build specific fixtures to help make sure whatever you need to build comes out exactly the way you envision!